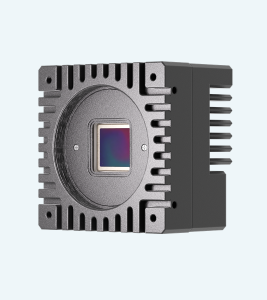

An industrial microscope camera is specifically created to record detailed images and videos in high resolution, which help it become a necessary quality control/research/inspection tool for many industries. High-Resolution ImagingThis is one of the prime aspects for which these cameras are known. Most provide a resolution of around 20 megapixels, or higher and some can resolve details down to the microscopic level. Industries like electronics manufacturing, for example, need this precision to avoid small defects in circuit boards or components from causing massive problems during production.

Another thing these cameras get right is the high frame rate. Images acquired by a large number of industrial microscope cameras can be grabbed at more than 60 frames per second (fps), meaning timely and real-time video capture if inspections are fast-paced. In the automotive industry, high-speed cameras capture images of engine parts as these move along conveyor belts thereby immediate defect detection.

Their ability to be used in any situation is key, however industrial microscope cameras are flexible. These cameras are available for virtually any microscope and can be mounted on a range of optical systems, rendering them suitable for numerous applications from materials science to biotechnology. In another example, biomedical researchers employ cameras to record cells so they can track their morphological structures and process over time. It is especially valuable for fields where long-term observation are necessary and the time-lapse imaging capability was another feature.

USB3. Industrial microscope cameras usually utilize 0 or GigE interfaces which means high-speed transfer rates. USB3. The GigE 0 can take advantage of a transfer speed up to 5 Gbps and also allows for distances with cameras connected via Ethernet LAN (Gigabit) connector upto 100 m. It is designed for easy incorporation into existing networks and ensures delay-free transfer of high-resolution images, a key requirement in real-time monitoring solutions.

Additionally, many industrial microscope cameras include adjustable exposure settings and white balance (color temperature) controls that play a key role in providing clear images across different lighting dependencies. This is especially important in metallurgy / material science where the lighting of your sample needs to be controlled, as non-controlled lighting from above can may or reveal defects on a surface or shwe light reflecting off some microstructures.

They are made to last with extensive built-in durability features, and operators working away in extreme industrial environments. Several industrial microscope cameras come with robust housing to avoid severe conditions — dust, vibrations and high temperatures. This effectively extends the life of your camera and ensures better functionality when working in tough conditions.

According to Dr Emily Roberts, a top microscopy researcher: “Overall, the new industrial microscope cameras are by far more precise and flexible than the older generation for carrying out detailed analyzes in complex fields as nanotechnology or electronics.” It illustrates the contribution that these cameras make to advancing industrial and scientific research.

These cameras boast excellent software integration capabilities as well. Advanced imaging software that comes with most models include Image Analysis for image analysis, Dimension Measuring Tool to measure dimensions and Diagnostics & Live reporting. This is paramount in quality control assays where measurements and recording must be accurate.

In sectors where an instant inspection is a necessary criterion the low latency of industrial microscope cameras means operators can take real-time decisions via live video due to this. It is mainly applied in semiconductor manufacturing, where the speed and precision to filter out defective products from entering the market should be very fast.

Ultimately the primary characteristics of an industrial microscope camera is high-resolution imaging, fast frame rates, solid connectivity and high degree of software integration making it a must-have tool for many sectors. More about Industrial Microscope Camera, please visit industrial microscope camera.